Indium Gallium Zinc Oxide: The Emerging Transparent Conducting Material

ndium gallium zinc oxide or IGZO is an amorphous oxide semiconductor material that has gained significant attention in the electronics industry in recent years. Known for its excellent optical transparency and electrical conductivity properties, IGZO is emerging as a promising alternative to indium tin oxide (ITO), the traditional transparent conducting oxide material used in touchscreens, LCDs and other optoelectronic devices. In this article, we will explore IGZO in detail - its properties, advantages over ITO, applications and potential to revolutionize the display industry.

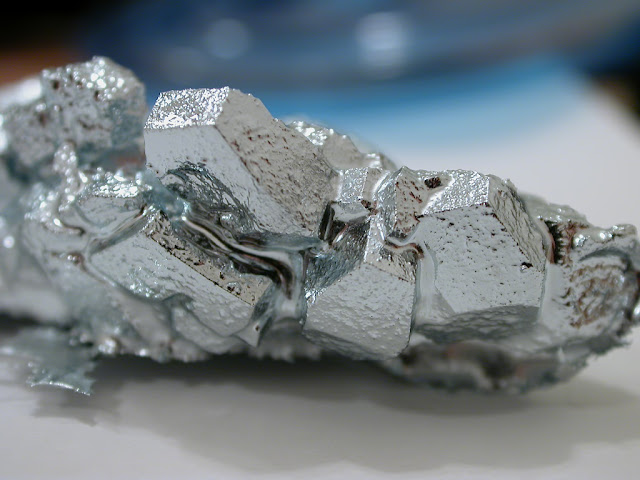

IGZO Composition and Structure

IGZO consists of indium, gallium, zinc and oxygen. The proportions can vary but

a typical composition would be In:Ga:Zn

in 1:1:1atomic ratio with excess oxygen. Unlike crystalline semiconductors,

IGZO has an amorphous structure which makes it easier and cheaper to

manufacture using techniques like sputtering. The electronic properties arise

due to a small overlap between the conduction band and valence band in its

disorderly atomic structure. This provides IGZO with high electron mobility

even in its amorphous state.

Advantages over ITO

ITO has been the mainstay transparent conductive material for decades but it

has some limitations. ITO is brittle, cracks easily and contains expensive

indium. On the other hand, IGZO offers several advantages over ITO:

Higher Electron Mobility: IGZO has much higher electron mobility of 10 cm2/V-s

compared to ITO's 10 cm2/V-s. This allows IGZO films to be much thinner while

maintaining good conductivity.

Flexibility: Being amorphous, IGZO films are highly flexible and do not crack

even when bent. ITO is rigid and prone to cracking.

Lower Resistance: Thinner IGZO films are sufficient to achieve the same or

lower resistance compared to thicker ITO films. This reduces costs.

Cost Effectiveness: IGZO does not use scarce indium and can lower costs

compared to ITO if indium prices rise further.

Wider Viewing Angles: IGZO has wider viewing angles compared to standard ITO

which is beneficial for displays.

Applications in Electronics

Due to its excellent transparency and conductivity properties along with other

advantages, IGZO with emerging wide applications in various optoelectronics:

Touchscreen Panels: IGZO is increasingly replacing ITO in touchscreen panels

used in smartphones, tablets and other devices. IGZO touchscreens offer better

visibility and thinner panels.

AMOLED Displays: IGZO thin film transistors are being used as the backplane for

driving active-matrix OLED display pixels. This improves display quality and

reduces power consumption versus LCDs.

LCD Displays: IGZO TFTs can drive LCD display pixels as well, reducing costs

versus standard silicon TFTs and enabling flexibility.

Flexible/Foldable Displays: Given its flexibility, IGZO is core to enabling

next-gen flexible and foldable displays that can be bent or folded.

Smart Windows & Lighting: IGZO has potential in applications like smart

windows, sensors and transparent displays that require highly transparent and

conductive layers.

The IGZO market is still in its initial growth phase but expected to rapidly

ramp up and reach $1.6 billion in revenues by 2025 according to some estimates.

As display manufacturers completely transition from ITO to IGZO-based touchscreens

over the coming years, the consumption of IGZO is projected to grow

substantially. With continuous research on, IGZO has the potential to

revolutionize next-gen displays and greatly enhance display technologies. IGZO

may herald the age of transparent, flexible, unbreakable and power-efficient

displays – truly a material worth watching out for in electronics.

In summary, IGZO demonstrates excellent potential as a transparent conducting

oxide material that could fully replace ITO in the future. With significant

advantages over ITO and emerging applications across touchscreens and displays,

IGZO is paving the way for next-generation electronics. As research progresses

on further improving its properties and manufacturing techniques, IGZO promises

to be a core material enabling the display technologies of tomorrow.

Get more insights on Indium

Gallium Zinc Oxide

Comments

Post a Comment